ShawnKevin

Member

- Messages

- 21

- Grill(s) owned

- Bull

I have a brand new, never cooked on Bull and can't stand the thought of grease and goo getting all over the front of my new smoker. After looking at the pictures and reviewing the posts on this thread I decided to wing it and try to make my own before it got dirty. After a lot of trial and error I found what will work for me. This is a transition for carpet trim and it's extruded aluminum. I have it mounted on the lid using the screw holes for the horns. Originally I drilled the first set of holes too low and the drip edge was hitting the front of the grill and would not close. I redrilled the holes, ensuring that the drip edge was further up and would not hit the front edge. I will need to find a way to cover up or fix the extra screw holes but some high temp rtv should do it (may not be pretty but it'll work). When closed, the drip edge tucks in side and will route any drips or grease into the barrel and not down the front. I plan on painting it high temp black to hide it a bit. I will also use the high temp rtv to seal the edge from the lid to the drip shield so nothing goes underneath. Attached is a Pic of the transition I used from home depot.

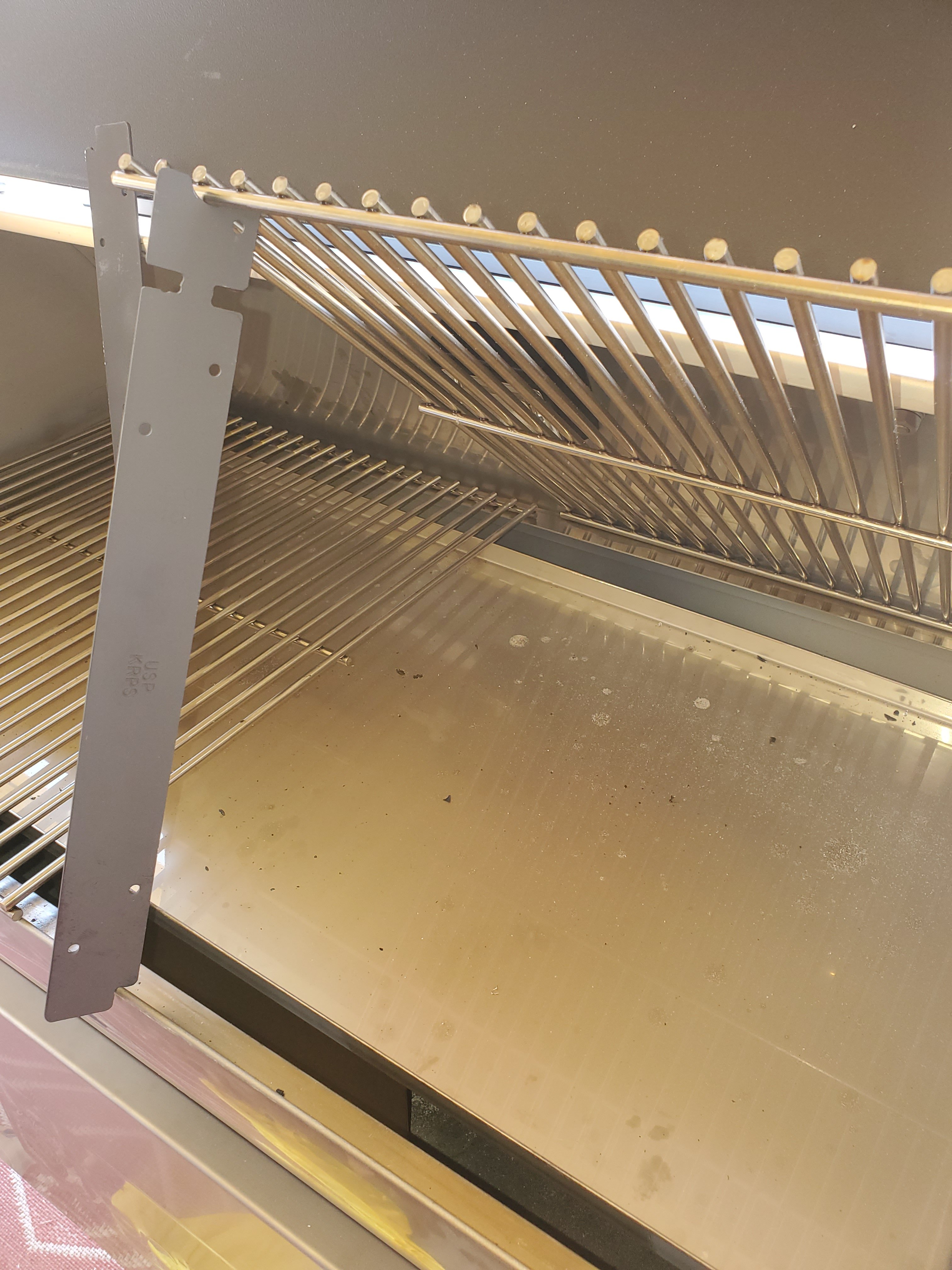

I also liked the Grill rack-jack so much that I decided to try to make a set as well. With the tools I have I was able to make a very functional, yet a bit ugly, set as well. The rack jack give me enough to room to lift the grates out of the way and replace foil on the drip pan or vacuum out the bottom without having to remove the dirty grates. The cuts on the sides fit between the grates to lift. There is also a cutout to hold the top secure when lifted and secure the bottom against the front lip of the grill. Attached is a picture of the metal strap I started with from home depot. It's also painted with high temperature paint in case I need to remove hot grates.

I'll post pics when it's done. Just an update on the progress so far.

I also liked the Grill rack-jack so much that I decided to try to make a set as well. With the tools I have I was able to make a very functional, yet a bit ugly, set as well. The rack jack give me enough to room to lift the grates out of the way and replace foil on the drip pan or vacuum out the bottom without having to remove the dirty grates. The cuts on the sides fit between the grates to lift. There is also a cutout to hold the top secure when lifted and secure the bottom against the front lip of the grill. Attached is a picture of the metal strap I started with from home depot. It's also painted with high temperature paint in case I need to remove hot grates.

I'll post pics when it's done. Just an update on the progress so far.