flippingeo

Well-known member

Hello fellow RT friends. I know you are just sitting there, watching football and wishing you had some long winded post on the RTF to read. Well you're in luck! I just replaced the factory 2RPM auger motor with an aftermarket 3RPM motor in my RT-590. And here's my story.

Issues Identified:

Dates/Conditions

Started the pit with a setpoint of 225°; Record time to setpoint.

Opening pit for defined times and recording max temperature drop/rise and time back to setpoint (stable). Once setpoint was reestablished, I held for >=15 mins before next test to stabilize. Reported below as (LOSS; RISE; TIME TO SETPOINT).

500° Ramp Up Tests

Adjusted setpoint to 500°; Record time to setpoint.

Opening pit for defined times and recording max temperature drop/rise and time back to setpoint (stable). Once setpoint was reestablished, I held for >=15 mins before next test to stabilize. Reported below as - TEMP LOSS; TEMP RISE; TIME TO SETPOINT).

Max Temp Tests

Yup! It's now time to see how high this sucker can fly. Adjusted the setpoint to FUL and placed GrillGrates (GG) flat side up on right side. Observed and documented temps at defined milestones. GG measured with Thermoworks IR-GUN-S. Reported below as - PIT TEMP/GG SURFACE TEMP.

Supplemental FUL Test

Last night the cold front came through and cooled us off substantially. I wanted to do a cold start FUL test with the 3RPM. Here are the results:

). Pretty sure it took me no more than 30 mins, and that includes time trying to figure out whether I could use the SmokeDaddy motor bracket. Some notes though:

While you're in there, go ahead and clean things up. Keyboard duster, Swiffer, whatever you have lying around. Bugs find it to be a safe place.

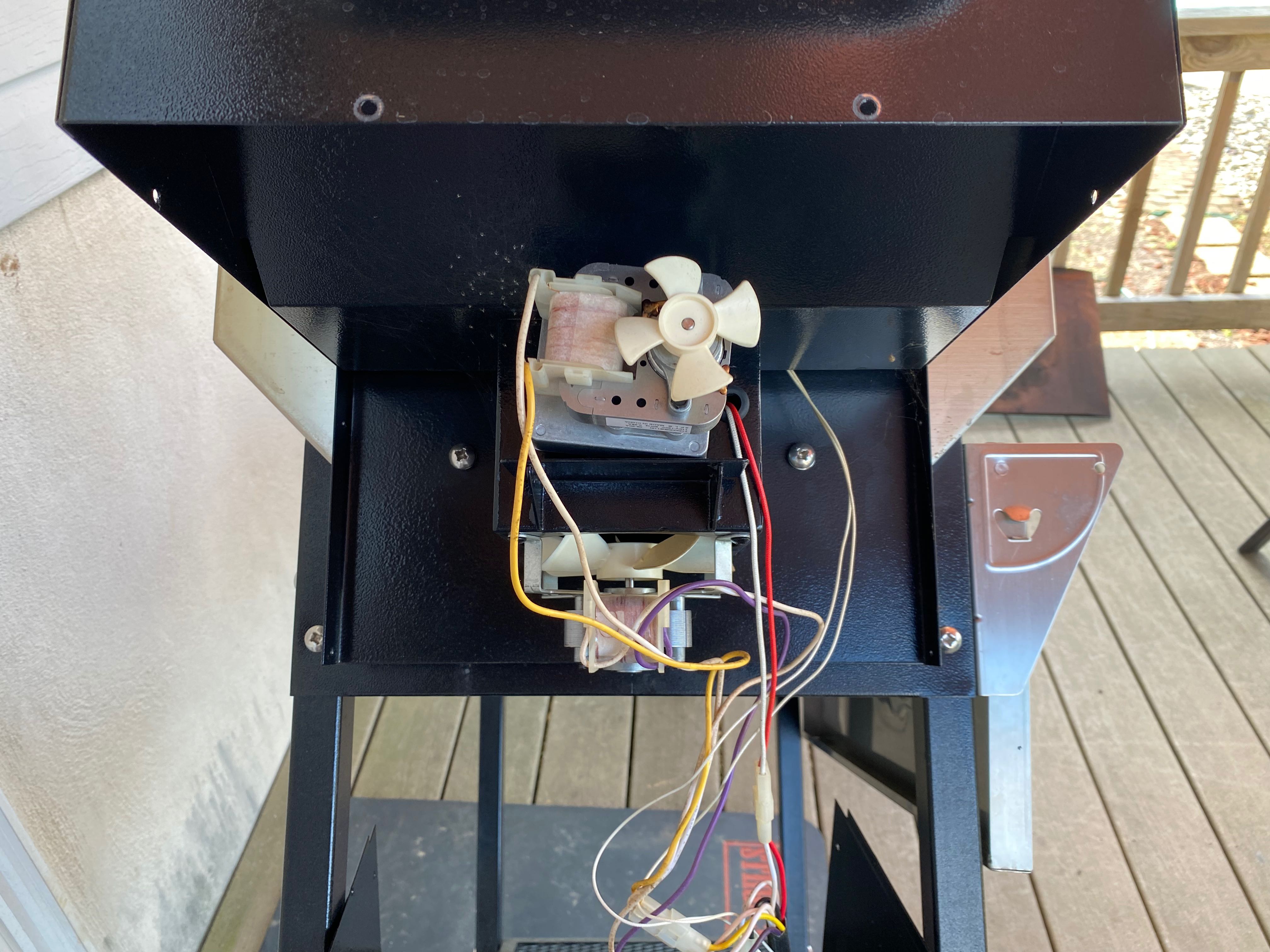

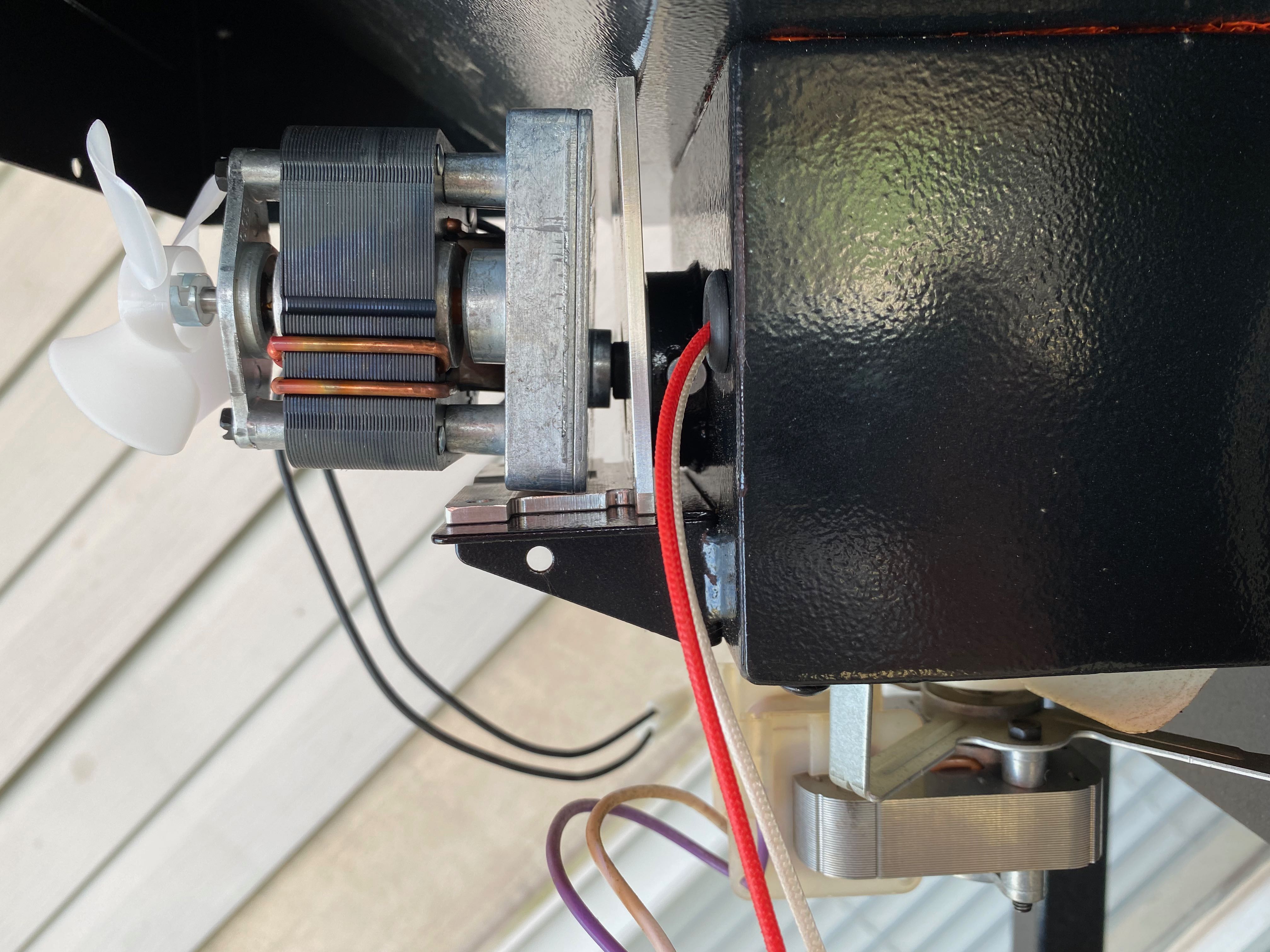

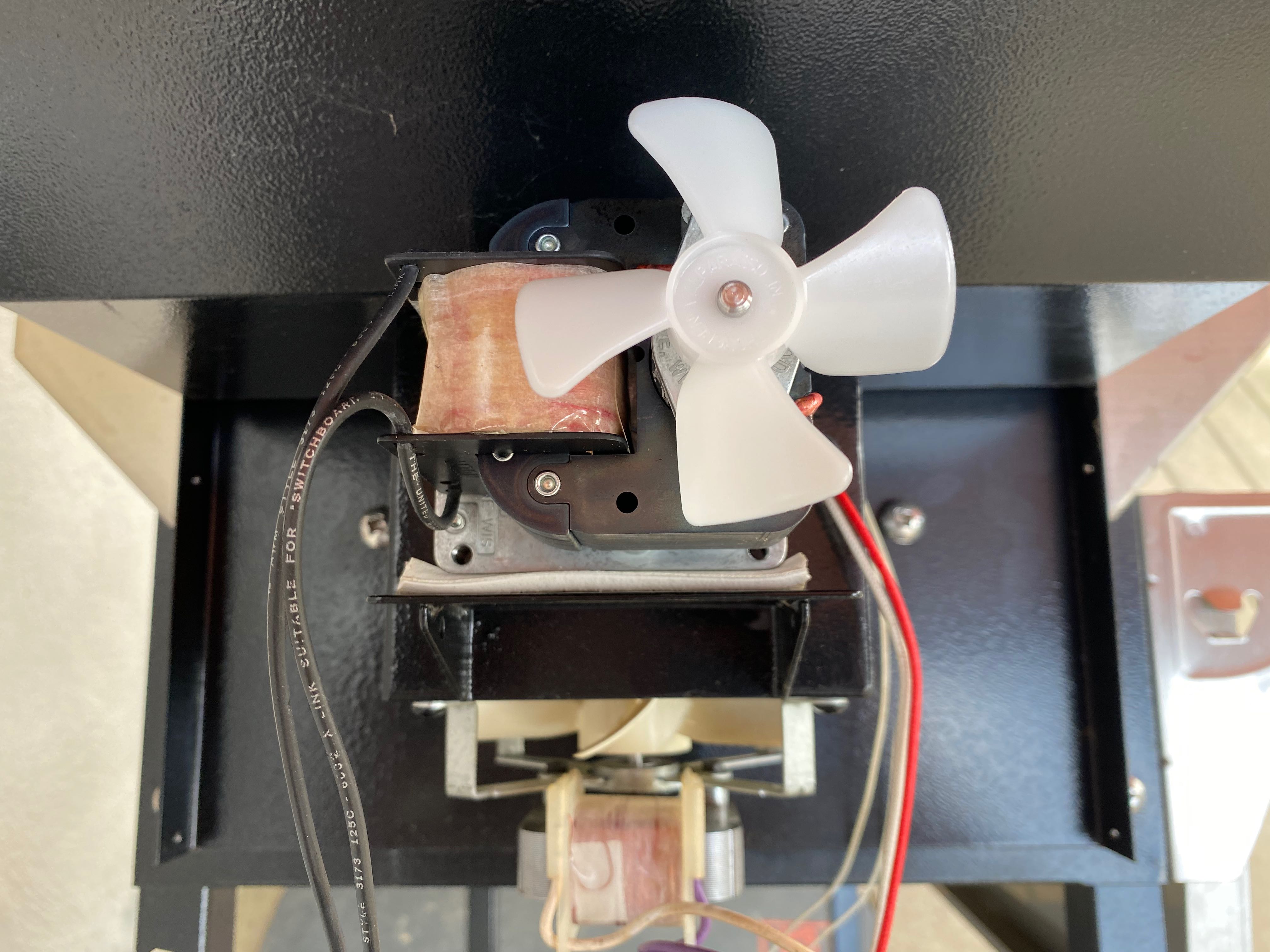

SmokeDaddy Motor bracket just didn't have enough clearance to use. As you can see from the photos, the factory motor is only supported by the auger shaft and a small plate under the motor. In the first picture you'll see the motor is crooked as there is play between the motor and the plate. I did end up putting a small piece of weatherstripping on the plate to reduce the twisting of the motor. Not sure how necessary it is though.

But either way, this is concerning. I will keep an eye on this in my next few cooks. I'm in MD, so we are almost always humid. Though I've never noticed moisture in the hopper before.

Overview

When I bought my RT-590, this was my first direct exposure to pellet cookers. I had an aging, mid-range gasser and a 22" WSM I'd use for slow cooks. The gasser was in need of replacement, and the WSM was always more effort than I was looking for. So with months of research I landed on the RecTeq 590. It seemed like it would be a great way to consolidate my cookers. When I got it I loved it. Slow cooks became so much more hands-off and the smoke flavor was nothing short of the WSM IMHO. But, I quickly discovered that it wasn't a great alternative to a gasser for the quick cooks, searing, etc. So then I began researching what I could do to rectify this situation.Issues Identified:

- Slow heat-up times for anything above 300° (30 mins in some cases just to get to 350°). God forbid I wanted 400°. I'd have to start the thing at breakfast to grill for lunch or early dinner.

- Even with Grill Grates, searing was just not feasible, or at least ideal, even if I wanted to wait an hour for the thing to heat up.

- When my wife wants a hamburger she only gives me a 30 min notice, and I must deliver. My RT-590 just wouldn't allow me to satisfy her.

- Impromptu "grilling" just isn't feasible, every cook must be planned out in advance.

- Purchasing another cooker (Bullseye specifically), but I really didn't want another cooker.

- Attaching CampChef, or equivalent, sear box (Still an option).

- Modify the RT-590.

The TL;DR Version

- What did you do? - I replaced the factory 2RPM auger motor with a 3RPM aftermarket motor found at SmokeDaddyInc.com - https://smokedaddyinc.com/product/3rpm-auger-motor-made-in-the-usa/

- Should I also get the Aluminum Auger Motor Stabilizing Bracket? - No. There isn't enough clearance to fit. (See details below).

- Was it easy to do? - Yes it was. Simply follow the instructions here -

- Did it fit without modification? - Yes it did. The upgraded replacement motor from SmokeDaddyInc.com fit perfectly.

- Did it make a difference? - Yes it did. I was able to reach temperatures at breakneck speed relative to the factory motor. I gained over 60° (12%) in max temperature, and ~70% gains on durations to setpoints. Substantial differences. All the gory details below.

- Anything negative to report? - TBD with further testing. I did realize some larger swings with the pit open tests. While it recovered much faster than the factory motor, it did swing quite high on some tests at 225° which is not great. However, this wasn't consistent so I'd like to do some further testing. It also seems a bit less stable at typical smoke temp (225°) which I don't like, but I'm going to try some cooks and see what happens. The 2RPM motor would hold dead nuts 225° for hours on end so expectations are a bit high.

- Would you recommend it? - It depends. If you are not having issues with your RT-590, only do slow/lo cooks on it, I wouldn't recommend it. If you struggled like me and looking to try something before buying another cooker, then yes. I recommend it. Based on other's experience, I would also explore the 2.5RPM motor. I'm looking to do that as soon as the motors become available. Others have reported lesser swing ranges than with the 3RPM.

The Details

OK. For the rest of you who like this stuff, and want to read on, here are the gory details of this project.General Information

- Model: RT-590

- Min Feed Rate: 6.5%

- Temperature Calibration (Pit probe offset): +11%

- Pellets: RecTeq Ultimate Blend

Testing Preparations

Conducted a series of tests that could be used to compare the 2RPM and 3RPM motor.- Clean the grill, scrape the drip pan

- Calibrate meat probe using ice water calibration process

- Set pit to 225° and place probe in center about 1" above grates

- Let pit reach target and hold for 30 mins to stabilize

- Adjust offset as needed for pit/probe alignment

- Remove probe

Testing Process/Results

This section describes the testing process and presents the results. I colocated the tests/results for easy comparison. I would have liked to have exported the Temperature History Charts, but unfortunately there is no way to do that in the app. I was going to grab screenshots and stitch them together for comparison, but honestly forgot. However these are the actual numbers realized at each phase of the tests.Dates/Conditions

- 2RPM - Sunday, Oct 10, 2021

- Environmental Conditions - Overcast/Cloudy; 65°; Winds 10 MPH/22 MPH Gust; RH 90%

- 3RPM - Saturday, Oct 16, 2021

- Environmental Conditions - Overcast/Incoming cold front; 72°; Winds 16 MPH/26 MPH Gust; RH 76%

Started the pit with a setpoint of 225°; Record time to setpoint.

- 2RPM

- Start time - 10:45A; Time setpoint reached - 11:05A; 20 mins to setpoint from ambient.

- 3RPM

- Start time - 1:00P; Time setpoint reached - 1:06P; 6 mins to setpoint from ambient.

- Actually topped over at 227°. Blower fan was in constant intermittent mode. Blew for ~5 secs then paused for ~5 secs. Interestingly it does not really hold 225° like the 2RPM motor, it ranged +/-3°. Blower continued intermittent operation which is atypical of 2RPM.

- Start time - 1:00P; Time setpoint reached - 1:06P; 6 mins to setpoint from ambient.

- 3RPM

- At 30 mins, I lost fire (flameout). Dropped to 192° and never recovered. Pit eventually dropped to 130°. Stopped test to investigate. Firepit was empty, so I suspected auger jam or motor failure. I turned it back on to see if auger would run, it didn't I placed a handful of pellets in the pit and they ignited. Shortly thereafter the auger started operating. Hit 225° in about 5 mins. No more issues and seemed to be ok to move forward with tests.

Opening pit for defined times and recording max temperature drop/rise and time back to setpoint (stable). Once setpoint was reestablished, I held for >=15 mins before next test to stabilize. Reported below as (LOSS; RISE; TIME TO SETPOINT).

- 2RPM

- Open 15 seconds: No loss; No rise; Stayed at setpoint

- Open 30 seconds: 223°(-2°); 227°(+2°); Back to setpoint in 10.5 mins

- Open 60 seconds: 188°(-37°); 228°(+3°); Back to setpoint in 22.5 mins

- 3RPM

- Open 15 seconds: 198°(-27°); No rise; Back to setpoint in 2 mins

- Open 30 seconds: 187°(-38°); 245°(+20°); Back to setpoint in 13 mins

- Open 60 seconds: 215°(-20°); 228°(+3°); Back to setpoint in 13 mins

500° Ramp Up Tests

Adjusted setpoint to 500°; Record time to setpoint.

- 2RPM

- 31 minsto setpoint from 225°

- 350° at 6 mins; 400° at 9 mins; 450° at 14.5 mins;

- 31 minsto setpoint from 225°

- 3RPM

- 9.5 minsto setpoint from 225°

- 350° at 5 mins; 400° at 5:45 mins; 450° at 7 mins

- 9.5 minsto setpoint from 225°

Opening pit for defined times and recording max temperature drop/rise and time back to setpoint (stable). Once setpoint was reestablished, I held for >=15 mins before next test to stabilize. Reported below as - TEMP LOSS; TEMP RISE; TIME TO SETPOINT).

- 2RPM

- Open 15 seconds: 476°(-24°); No rise; Back to setpoint in 4 mins

- Open 30 seconds: 429°(-71°); No rise; Back to setpoint in 12.5 mins

- Open 60 seconds: 394°(-106°); No rise; Back to setpoint in 12 mins

- 3RPM

- Open 15 seconds: 492°(-8°); No rise; Back to setpoint in 2 mins

- Open 30 seconds: 450°(-24°); 536°(+36°); Back to setpoint in 14.5 mins

- Open 60 seconds: 357°(-143°); 541°(+36°); Back to setpoint at 15 mins

Max Temp Tests

Yup! It's now time to see how high this sucker can fly. Adjusted the setpoint to FUL and placed GrillGrates (GG) flat side up on right side. Observed and documented temps at defined milestones. GG measured with Thermoworks IR-GUN-S. Reported below as - PIT TEMP/GG SURFACE TEMP.

- 2RPM

- At 15 mins: 498° / 533° - From 500°: +/-0° / +33°

- At 30 mins: 519° / 548° - From prior: +21° / +15°

- At 60 mins: 536° / 563° - From prior: +17° / +15°

- 3RPM

- At 15 mins: 602° / 620° - From 500°: +102° / +120°

- At 30 mins: 600° / 635° - From prior: -2° / +15°

- At 60 mins: 600° / 645° - From prior: +/-0° / +10°

Supplemental FUL Test

Last night the cold front came through and cooled us off substantially. I wanted to do a cold start FUL test with the 3RPM. Here are the results:

- Environmental Conditions - Partly Sunny; 55°; Winds 15 MPH/26 MPH Gust

- 500° at 17 mins after start

- 600° at 25 mins after start

- Held at 600° for over an hour

- Recorded max GG temp just over the fire box at 657°

Replacement Notes

Its easy. Just watch this video (While you're in there, go ahead and clean things up. Keyboard duster, Swiffer, whatever you have lying around. Bugs find it to be a safe place.

SmokeDaddy Motor bracket just didn't have enough clearance to use. As you can see from the photos, the factory motor is only supported by the auger shaft and a small plate under the motor. In the first picture you'll see the motor is crooked as there is play between the motor and the plate. I did end up putting a small piece of weatherstripping on the plate to reduce the twisting of the motor. Not sure how necessary it is though.

Comments/Issues

Now, in addition to the temp swing issues with the 3RPM and the flameout I experience on the first test, there was something else I noticed that I want to mention. At this point, I still don't know if it is related to environmental conditions, or whether these new high heats are literally forcing the moisture out of the pellets, but on FUL I realized substantial condensation in my hopper. I'm diligent about how I store my pellets, and they are always dry. Now the pellets that were in the hopper likely grabbed some moisture from this recent Oct heat/humidity wave we've had, so that is certainly possible.But either way, this is concerning. I will keep an eye on this in my next few cooks. I'm in MD, so we are almost always humid. Though I've never noticed moisture in the hopper before.